Rice is the staple in the diet for much of the world. It runs a close second to wheat in its importance as a food cereal in the human diet. About 560 Million Metric Tons of rice are grown annually compared to 600 MMT for wheat, 300 MMT for oil seeds, and 900 MMT for coarse grains (corn, sorghum, barley, oats, rye, millet and mixed grains.) Most coarse grains go into animal feed where its impact on the human diet is not as great (eight lbs. of grain are needed to produce one lb. of beef). Rice produces more food energy per acre than other cereal grains, and is second only to wheat in terms of protein per acre produced. Rice production has more than doubled in the last 40 years. Most of the increase in production has been a result of improved field yields. Acreage planted in rice has only increased about 30 percent. Rice is best grown in flooded fields and so acreage is limited by soil type and supply of water.

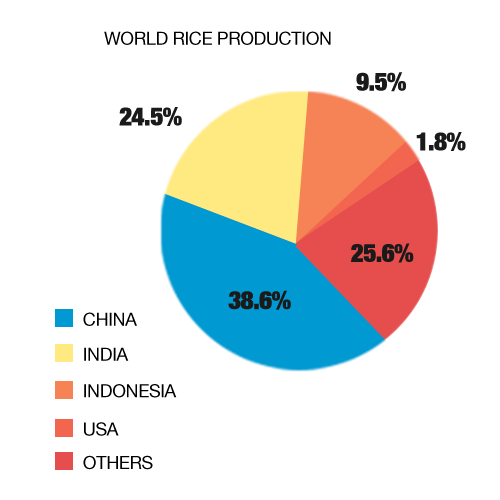

Of the 560 MMT produced almost 60 percent is grown and consumed in China and India. The leading producers of rice, are (in order) China, India, Indonesia, Bangladesh, Vietnam, Thailand, Burma, Japan, Philippines, Brazil, and the United States. The United States produces about 8 MMT, or about one and one half percent of the world’s supply. Most rice is consumed within a few miles of where it is produced. Very little rice is traded and for this reason the market price for rice is very volatile. In the case of wheat and coarse grains 15% of the world’s production is traded between countries. In the case of rice only 5% is traded. The United States has historically exported about half of its production, and for many years, the U.S. was the number two exporter of rice in the world behind Thailand. Today Vietnam is number two and occasionally India takes the number three slot. Following are the top five exporters and importers for 1999: (quantities are for milled rice, about 68% of paddy rice)

Rice is different from all other crops in that it is usually grown in a flooded field. The base of the rice stalk will be under water most of the growing season. Rice can be grown on dry ground and is sometimes grown in that manner in developing countries, but the field yields are much lower and quality is lower with dry land rice. Rice is essentially a type of grass. It is an annual and happens to grow well in water. When grown on dry land other grasses and weeds can overtake rice and dramatically reduce field yields and quality. (There are no herbicides that can selectively kill other grasses without killing rice.) Controlled flooding of rice fields is a very effective means of weed control and rice flourishes in water. In areas with short growing seasons, the rice only yields one crop. In some areas after cutting, the rice is allowed to grow back and produce a second crop. Rice typically needs about 120 days of warm sunny weather to grow and mature, rice needs soil that can hold water. (Imagine trying to grow rice on sandy land.), and there must be an abundance of water to economically grow the crop. For mechanized farming, the land must be able to be drained and hold heavy equipment. These factors limit the acreage where rice can be grown.

Most rice is still grown the old fashion way, by hand. The seeds are germinated and the seedlings carefully grown until they reach a certain level of maturity. They are then transplanted by hand into flooded fields. They are usually planted in rows with space between the plants. They are put in the flooded soil one at a time. Weeds are pulled by hand until the rice has grown too thick for labors to walk through the field. Fertilizers are spread by hand. Sometime before harvest, the water is pulled from the field and the ground is allowed to dry. The rice ready for harvest is often cut by hand. In some countries, the straw with the rice attached is stacked in a special manner to dry. In other countries, the rice is threshed and spread on the ground, pavement, or highway to dry. It is surprising to see in some advanced countries like Japan, most of the work is still done by hand. There are small machines to facilitate the planting of the seedlings. A mechanical harvester cuts most of the rice in Japan, but the harvester is only a few feet wide. The rice is still dried in the field.

Rice is one of the most beautiful crops in the world. The level of the water is critical to the well being of the plant. Ideally, there should not be more than a two-inch variance in the depth of the water within a field. For this reason, you see the beautiful curving lines of levees around the fields of rice. Winding terraced fields are formed in the following manner: Start at the highest point of the field and then go out as far as possible without dropping more than two inches in elevation and make a levee. If the land is not flat, then the levee will not form a perfect circle or square. It will take its own unique winding shape. From that first levee, go out as far as possible and make another levee without dropping more than 2 inches in elevation. Continue in this manner throughout the field. Pump water into the field of highest elevation and then allow the water to flow over a level control gate into the next field and then the next. The result is a very strange and beautiful pattern of fields surrounded by winding levees.

Rice from the field is harvested and threshed to produce what is most often called paddy rice or rough rice. Rice is usually harvested at about 18% to 24% moisture and must be dried down to about 12% to 14% so that it can be safely stored. In most developing countries rice is somehow air-dried. The straw and rice can be dried in the field. It is sometimes stacked in a special manner to allow air to pass to through it and cause rain run off quickly. Most often, the paddy rice is spread on some sort of concrete or pavement and raked over until dry. In some developing countries, you will see rice drying all over the roads during harvest season. In more developed countries, rice is dried in farm storage bins that have air chambers underneath that force air to pass up through the rice, or rice is dried in large column dryers where the rice makes two to five passes through the dryer in a continuous flow type system. Drying of the rice (including while in the field prior to harvest) is a critical component in regards to quality. Rice that is cracked during drying will have a lower percentage of head yield and will have a poorer quality after cooking.

Milling of the rice involves; removing the trash and then the husk from the rice, milling the bran off of the endosperm (leaving white rice), and then removing broken kernels and other defects. There are many ways that rice can be stored and milled. In much of the world, the rice is milled in very small mills near the farm and stored in the form of milled rice until consumed. Sometimes it is stored as paddy or brown rice and then milled fresh prior to consumption. Thailand, Japan, and the U.S. are good examples of how different the systems can be.

• In Thailand, most rice is milled to white in small mills near the point of harvest and very soon after harvest. The rice is then stored in 50 or 100 KG jute bags in a small storage shack or in a farmers home. At some point, the rice will be sold to a large rice milling and trading company in Bangkok. The milled rice in jute bags will accumulate in a large warehouse in Bangkok where it will usually be remilled and blended for the export market.

• In Japan, the rice will be husked and made into brown rice near the field soon after harvest. These brown mills can be very small or can be as large as 100 ton per day (brown mills are usually operated by a cooperative). The brown rice is packed in woven poly bags and stored in cool temperature and humidity controlled warehouses until ready for milling. Japanese rice mills tend to be the most sophisticated in the world, but are rarely more than 100 MT per day. (This is relatively small when compared to U.S. mills that can handle 1000 MT per day.) The Japanese are extremely particular about rice quality. They go to great lengths to prevent cracking of the rice (humidity controlled warehouses to maintain moisture at 14% to 15%) and they believe that rice is best when served fresh after milling. There are many stores in Japan, where small machines mill brown rice as it is purchased. (Of course this obsession with quality has a price and Japanese rice is about 5 times the price of rice in other countries.)

• In the United States, most of the rice is dried and then stored in large commercial dryers. The rice is stored in the form of paddy rice. It remains in bulk in the paddy form until time for milling. The paddy rice will be shipped via truck, rail, or barge in bulk to a large mill where it will be milled and packed for either the domestic or export market. This is a very efficient system. Freight is cheap in the U.S. and so transportation of paddy rice (which involves the unnecessary hauling of husks and bran) to a large central milling location makes sense. Most smaller mills in the U.S. handle at least 200 MT per day (milled basis) and the largest mills can mill up to 1000 MT per day. In the U.S. the milling operation is year round and not just at harvest.

In the U.S., Japan, Australia, Europe, and now some of the developing world, the milling of rice has become a very sophisticated process. Following is a description of the basic components of the process.

Grain Cleaning. The paddy rice is passed through coarse screens to remove all straw, stones, and other objects that are larger than the rice. The rice passes over fine screens to remove small weed seed, sand and dirt, stones, and other objects smaller than the rice. Air separation systems are sometimes used in this process.

Destoning. The rice is passed through a specific gravity table that separates the product by density. Stones are separated from the rice.

Husking. The husk is removed from the rice. This is most often done by passing the rice through two spinning rubber roles. One roll is spinning faster than the other. The rubber rolls are tightly pressing against the rice from both sides and strip the husk off.

Paddy Separation. A portion of the rice leaving the husking operation still has the husk on the kernel. A paddy separation machine that works with specific gravity separates the light paddy kernels from the heavy brown (husks removed) kernels. The paddy kernels go back to the huskers.

Milling. There are many machines and methods designed to remove bran from the rice. The Japanese milling system is most often used in the most modern mills. With this system, the rice is first passes through a milling chamber that has an abrasive stone spinning in the center and a scarified metal screen on the outside. (The abrasive system). The rice then passes through a milling chamber that has a metal roller spinning in the center and a scarified metal screen on the outside. This machine is rubbing the many kernels of rice against themselves and the screen in order to remove the bran. (The frictional system.) The last pass (sometimes all frictional passes) is basically another frictional machine that is applying a mist of water to facilitate milling and add a smooth polished surface to the rice. (The water polishing system.) This Japanese system can be done in three passes as described here, or as many as seven passes.

Broken Removal. Milling the rice can yield as many as 4 to 40 percent broken kernels depending on the quality of the incoming rice and the milling equipment. Most high quality rice is sold with less than 4 percent brokens and so brokens must be removed in the milling process. The rice is passed through indent graders. These can be cylinders with small pockets too small for whole grain to fit into, but just right for brokens, or disks within a trough that have similar indents. Either way, the idea is for the brokens kernels to temporarily fit into the indent so that they will be picked out of the whole kernels and then thrown into a separate flow. The brokens can then be passed over screens or additional indent graders to be further separated into various sizes. (brewers, screening, and second heads).

Sorting. The milled whole kernel rice is passed through an electronic sorter to remove defects. The rice is passed before an electronic eye that detects any difference in color. A jet of air removes defects. Usually damaged kernels (with black specks), yellow kernels, and stones are removed. The very best mills pass the rice through two breaks of sorters. Sorters can be adjusted to remove green immature kernels from brown rice, chalky rice from white (more translucent kernels) rice, or regular medium grain rice from chalky mochi rice.There are special sorters to remove glass from rice.

Magnets. There are usually magnets throughout the milling system to remove metal that can damage machinery and get into the rice. Many have a non ferrous metal detectors (can remove all metal including aluminum and stainless steel) just before packaging as a final safeguard.

Paddy Rice or Rough Rice

Brown Rice

Milled Rice

Broken Rice

Rice Bran and Stabilized Rice Bran

Organic Rice

Parboiled Rice

Instant Rice

IQF Frozen Rice

In most of the world and in California, the term paddy rice is used to describe the rice as it comes from the field after harvest. The rice has been threshed and each grain is separate. The grain of rice has a hard husk protecting the kernel inside. The husk (or hull) that covers rice is much thicker and tougher than most cereal grain husks. Paddy rice is also called rough rice. (Primarily in the southern growing area of the U.S.) By weight, the composition of paddy rice is approximately: 22% husk (including about 2% trash), 10% bran, and 68% rice (2% of the rice are very small pieces, brewers rice, and fines). The rice portion can have varying percentages of broken kernels. A typical milling yield in California for medium grain would be described as 54/68. 54% brokens and 68% total. (14% brokens) In the southern growing area, a typical yield for long grain would be 58/68. In Japan where harvest and drying conditions are ideal a typical yield would be 67/70. Paddy rice is not as dense as milled rice and usually weighs about 37 lbs per cubic ft. Brown rice, milled rice, and brokens weigh about 52 lbs per cubic ft. Most paddy rice is milled in the U.S. Some is exported to countries like Brazil, Mexico, and Turkey for milling. The export of paddy harms the milling industry and eventually the farmer. The U.S. is about the only country in the world that allows the export of paddy rice. It does not make sense from an economic standpoint (the unnecessary freight cost of hulls and bran). It only occurs when the importing country has some sort of duty advantage for paddy rice that allows it to occur.

After the husk is removed the remaining product is called brown rice. Brown rice is more nutritious than white rice, but very little rice is consumed in the brown form. Brown rice contains a bran layer that is about 12% of the brown kernel by weight. The protein in white rice is much more nutritious than most cereal grains but has a low level of the essential amino acid, lysine. The protein level in bran layer of brown rice is higher and has more lysine. The protein in brown rice has one of the most complete essential amino acid profiles of any vegetable crop. (No vegetables alone are complete.) The rice bran layer of brown rice also contains digestible fiber as well as minerals and vitamins not found in milled rice. It was learned that incidences of beriberi were dramatically reduced when diets where switched from white milled rice to brown rice or even parboiled rice which contained more thiamin. The oil content of the rice bran contains several vitamin E components and valuable nutrients. Because minerals and vitamins are lost when the bran is removed, years ago many states passed laws requiring white rice to be fortified with vitamins and minerals. Despite its nutritional value, consumption of brown rice is low because it takes almost one hour to cook and many people do not care for the taste and texture. Unfortunately, once the husk is removed from rice, the bran layer starts going rancid and this contributes to the bitter taste of brown rice. Very little brown rice is actually consumed in the U.S. or the world for that matter. Some rice is exported in the brown form (primarily to Japan and Europe) for further processing.

Milled Rice has had the hulls and bran removed. It is also called white rice or polished rice. Most milled rice sold into the domestic market has been milled very hard and has had the broken content removed to below 4%. Less expensive rice sold to export markets may be milled to a lessor degree and may have higher percentages of broken kernels. State laws require that milled rice sold to U.S. consumers be enriched with vitamins to make its nutritional value similar to brown rice. For this reason, cooking directions mention that the rice should not be washed. (The enrichment is usually a powder and is easily removed with water.) Most ethnic consumers who eat a lot of rice wash the rice to improve taste and texture. Much of the Japonica rice packaged in California is not enriched and is labeled as coated with glucose (allowed by law) for these consumers who do not like the taste of enrichment and who were going to wash it away anyway.

Almost all rice is consumed in the milled form, and most rice exported from the U.S. is exported in the milled form.

The kernel of rice can become cracked in the field, during the drying process, or during the milling process. Cracks are usually caused by moisture migrating too quickly within the kernel (drying too fast, or moisture being added back to a dry kernel). Often these cracks cause the kernels to break during milling and so broken rice is generated. The percentage of broken kernels (relative to total milled rice) generated during milling usually ranges from 12% to 24% in the U.S. Most brokens are removed during the milling process to less than 4% in order to give the consumer a high quality rice. Broken rice tends to get mushy during cooking and makes a poor quality table rice. There are different sizes of broken kernels. With long grain rice in the south brokens are often separated into different sizes. From largest to small they are called; second heads, screenings, and brewers. In California, where the kernel is smaller to begin with, the brokens kernels are only separated into second heads and brewers.

In the past most broken rice in the U.S. went to the beer industry. Today, most of the rice going into beer is now whole kernel. The dog food industry uses the majority of the broken rice. They tend to start with the lower quality brewers rice and then move into the more expensive screenings and second heads as needed. The rice flour industry is growing and tends to use the higher quality sorted second heads and screenings. The beer industry still takes some of the higher quality second heads. Some brokens are now being exported to Japan out of California.

Southern Long Grain Rice

California Medium Grain Rice

Southern Medium Grain Rice

California Mochi Rice

Thai Jasmine Rice

Indian Basmati Rice

Arborio Rice

Wild Rice

There are many varieties of rice in the world. Rice comes in many shapes and even colors. In this section, we will focus on the types of rice that are available in the United States. Experimental Stations in the United States operated by the Dept. of Agriculture and some private companies are constantly developing new varieties in their search to improve field and milling yields as well as taste and texture. Within each type of rice, there are many types of varieties.

Several varieties of long grain indica type rice are grown in Arkansas, Mississippi, Missouri, Louisiana, and Texas. There are slight differences between varieties, and some varieties are kept separate for special processing like parboiling. This is the most common type of rice consumed in the U.S., and the world, as table rice. Similar types of rice are produced in most growing areas of the world. It is a long slender kernel, four to five times longer than its width. The amylose content of southern long grain rice is about 22 percent, and so the rice is a firmer and not as sticky as medium grain varieties. Gelatinization temperature is about 70 degrees centigrade, and protein content tends to average about 8%.

California medium grain japonica type rice is also known as calrose rice. There are two or three varieties grown in California (not including M401 type medium varieties), but they are so similar as to be indistinguishable. There is no effort to keep the varieties separate during milling and storage in California. This rice needs a special temperate climate and is only grown in a few places in the world. Japan, Korea, parts of northern China, Australia, and some countries around the Mediterranean sea. In terms of a bland, clean taste, this rice is probably the best in the world. In the major consuming counties, it is most often eaten alone, without flavoring. Medium grain rice is shorter and wider than long grain rice. The kernels are two to three times longer than its width. The amylose content of California medium grain rice is about 18 percent, and so the rice tends to be a little on the softer side and is sticky. The kernels cling together. Gelatinization temperature is about 60 degree centigrade, and protein tends to average 6.5%.

On paper, Southern medium grain appears to be the same as California medium grain rice. Shape and amylose content is the same. Gelatinization temperature and protein content is a little higher. But the southern medium grain rice is different. It is an indica type and so of a different origin. It is unacceptable to the palate of consumers of japonica type medium grain rice. Southern medium grain rice is not at white, not as sticky, and not as clean tasting as japonica varieties. There are consumers in places like the southern United States and Puerto Rico that like this type of rice, but they eat it along with spices, beans, meat, and sauces.

Indian Basmati rice is also an aromatic rice, but has a very different aroma and taste from Thai Jasmine. Some people describe its aroma as popcorn like. This rice is grown in the northern Punjab region of India and Pakistan, and commands the highest price of any variety of rice grown in the world. (not counting artificially high prices for rice in Japan.) This rice has a high amylose content and a firm almost dry texture when properly cooked. The raw kernel is long and slender like southern long grain, but slightly smaller. The kernels increase in length by more than three times when cooked to produce a very long slender cooked grain. The best Indian Basmati has been aged for at least one year to increase firmness of cooked texture and increase the elongation achieved in cooking. Once again, there are many "knock off" varieties grown in the U.S., but none match authentic Indian Basmati for favor, aroma, texture, and appearance.

Arborio Rice is an Italian variety of rice that is commonly used in risotto dishes. It is close to California medium grain in appearance and texture. It is a bigger kernel with a distinct chalky center. When properly cooked, arborio rice develops a unique texture with a starchy creamy surface and a firm bite in the center. There are varieties of arborio rice grown in California that are as good as Italian varieties. Sage V Foods markets a California variety of arborio.

Wild rice in not officially classified as rice, but is in fact a different type of grass that grows a long stalk and thrives in deep water. It was traditionally grown wild in the lakes of northern United States and southern Canada. It is still grown this way in Minnesota and other northern areas. Indians harvested the rice in canoes, and then parched (primitive parboiling) the grains. Much of the wild rice from Minnesota is still harvested and parched with methods similar to the past. Parching give the wild rice a strong flavor. All wild rice is sold with the bran on the kernel (like brown rice) and this gives it its black appearance. In California today, wild rice is mechanically farmed and harvested and then parboiled using modern methods. The quality of California rice is more consistent. Specialty Varieties in the United States. In the U.S. more and more specialty rice varieties are being grown for niche markets. There are several varieties of rice that have been developed to perform like Thai Jasmine and Indian Basmati. There are several varieties of rice that have unusual bran colors like Wehani, red rice, and black rice. In California today there are several Japanese short grain varieties being grown like Akita Komachi and Koshi Hikari.

Most people refer to the USDA grade sheet in referring to the different qualities of rice. The degree of milling, percentage of damaged kernels, and percentage of brokens are all important factors. But all rice that meets a US #1 grade is not the same (not even close), and from this point on the issue becomes much more complex. There are many factors that effect taste and texture, and this section will try and address most of those. Sage V Foods has a great deal of knowledge in this area that is proprietary and will not be disclosed in this document.

The USDA grade system and a US #1 grade. Go to United States Standards for Milled Rice for all the gory details of the different grades of rice. A US No 1, grade of long grain rice meets the following criteria:

• Less than 2 kernels in 500 grams of Seeds, heat-damaged, and paddy (singly or combined).

• Less than 1 kernel in 500 grams of heat-damaged and objectionable seeds.

• Less than .5% red rice and damaged kernels.

• Less than 1% chalky kernels

• Less than 4% broken kernels.

• Less than 1% other types

• Shall be white or creamy

• Shall be well milled.

In the US almost all rice sold to the consumer is of a higher quality than rice meeting the minimum requirements of a US #1. Each mill has its own standards for its package quality rice, but in general the improvements are made in the areas of milling degree and damages. Package Quality rice has a much harder milling degree and so the rice is whiter and cleaner tasting. Package Quality rice usually has fewer damaged kernels and impurities such as weed seeds and paddy.

Milling degree is an important factor for quality. Milling removes the bran layer. Rice bran is about 20 % oil and also is subject to very aggressive enzyme activity. Once the structure of the bran is disrupted lipase enzyme attacks the oil and creates free fatty acids. The bran becomes rancid very quickly. Any bran remaining on the rice affects the taste. Milling the rice very hard improves whiteness and flavor.

Broken rice gets soft and mushy when cooked. From a nutritional standpoint, brokens are the same as whole grain. But the texture is poor and brokens tend to have more bran, which affects flavor.

Obviously weed seeds, paddy rice, and other impurities affect the appearance of the rice. Small weed seeds like water grass can go unnoticed, but affect the flavor when cooking. In California, adobe balls (hard balls of clay) and often stones get in the rice. The USDA system does not properly account for adobe balls and allows many to be in the rice.

This is a very complex area and there is still much to be learned. The nature of rice starch differs depending on variety, growing area, and crop year. The nature of the starch affects texture and retrogradation properties of the rice. Most people knowledgeable about rice have heard of amylose and amylopectin. These are two different types of starches. Amylose is a long chained starch without a lot of branching (like a pine tree), and amylopectin is a shorter, but much more highly branched chain of elements (like an oak tree). Indica type long grain rice has 22 percent amylose and 78 amylopectin. Japonica medium grain rice has 18 percent amylose and 82 percent amylopectin. In general rice with more amylopectin is softer, sticker, holds moisture better, and is more resistant to retrogradation. The amylopectin/amylose ratio does not explain all textural issues related to rice, but is a very important factor.

Protein levels in rice range between 5 and 10 percent. The level of protein differs depending of variety, growing area, and crop year. In general, rice protein has a bad taste and so the rice tastes better with less protein. Protein also probably affects the texture of the rice in ways that we do not understand.

This is probably the biggest factor affecting the quality of cooked rice and yet is the least understood. The quick migration of moisture through rice causes cracking in kernal. Quick changes in temperature can cause cracking. These can be cracks that are large enough to open up and cause the rice to break during cooking, or that can be small fissures throughout the kernel. The problems with cracking start in the field. If rice is near harvest moisture contents of 20 to 26 percent and starts to dry too fast (due to dry winds, for example), then the rice will develop cracking while in the field. If the rice is dried to fast in commercial dryers, then cracking can occur. Cracking can occur in milling (especially in older frictional mills) where milling temperatures get high. The sudden release of surface moisture or change in temperatures can cause cracking. The pressure applied in milling can cause cracking. When the rice is cooked, open cracks allow moisture to enter the kernel too quick. There is too much surface area where starch is leached out. The kernel does not maintain its grain shape and get mushy. There are some theories that cracking releases enzymes that affect flavor.

The moisture of the rice prior to cooking also affects texture. If the moisture is below 13%, the quick movement of water will cause cracking. The lower the moisture, the greater the cracking. Once again, rice that cracks will have a poor cooking texture.

This is another area where little is understood. The Japanese believe that good rice is alive, (good rice while in the paddy or brown form will germinate and grow.) and so they prefer to eat rice fresh after milling. Age creates changes in the nature of the starch. Rice gets harder with age as if the percentage of amylose is increasing (it is not). The rice gets firmer and less sticky. Most older rice loses moisture and so the cracking problem during cooking occurs. If there is any bran on the surface of the rice due to loose milling, then the rancidity problem causes poor flavor. Any insect problems while in storage affects odor. Aromatic rice like Thai Jasmine lose their aroma with age. Sticky types of rice like Japonica short and medium grain rice are best consumed immediately after harvest. The texture of parboil rice does not change much with aging. Some harder rice like Indian Basmati are best consumed after several years of aging. But Indian Basmati is an exception, in general aging of rice deteriorates quality.

Cooking Rice is a Science. Everyone seems to have his or her own method of cooking rice. Cooking instructions on rice packages differ a great deal and cookbooks further confuse the issue with additional methods of cooking rice. Sage V Foods cooks rice on a commercial scale every day of the week. There are some basic scientific principles that take the black art out of cooking rice. For almost all types of white rice, the best quality is achieved when the rice is washed, soaked, blanched or boiled, and then steamed.

Ratio of water to rice. This is the area where most people have trouble cooking rice. Most rice is perfectly cooked when the final moisture content is between 58% and 64% moisture. At lower moisture contents, the rice is firmer. The final moisture content is a matter of preference and preference can differ with the type of rice and final cooked application. The math is very simple; 100 grams of rice with a starting moisture content of 12% needs 110 grams of water to be fully cooked at 58% moisture. 100 grams of rice with a starting moisture of 12% needs 145 grams of water to be fully cooked at 64% moisture. One cup of rice weighs about 205 grams. The same cup of water weights about 240 grams. If no water is lost in the cooking process, one cup of water is enough to cook one cup of rice, and yet most recipes call for two cups of water to one cup of rice.

It all comes down to how much water is lost in the cooking process. This is a matter of time required to cook and the nature of the cooking container. Most white rice cooks in 15 to 20 minutes. Instant rice or presoaked rice that cooks in half the time requires less water (Not half as much. Half as much is lost as vapor, but the rice takes up a constant amount.) Brown rice that takes 45 to 60 minutes to cook requires much more water because of the vapor loss, even though the final moisture content of the rice is the same as white rice. If the lid is off, much more water is needed. If the lid is really tight (like in a good rice cooker), very little extra water is needed. The width of the pot (surface area of the rice) affects the water loss. A deep narrow pot requires less water than a wide shallow pot. Following are some simple examples of existing instructions: A good rice cooker may call for one cup of rice and one cup of water. Most instructions on packages of regular rice call for one cup of rice and two cups of water. (You will need a pot that loses a lot of vapor to evaporate a cup of water and make that rice come out well.) Instant rice recipes call for a cup of rice and a cup and a half of water. Instant cooks in half the time and so if you are using the same pot that works with 2 to 1 on regular rice, the rice will cook properly.

Unfortunately, everyone uses different cooking containers, and so rice cooking instructions rarely work out. Trial and error will yield the best results. Keep in mind that when using the same pot, when more rice is added and the water is at a deeper level, the same amount of water will be boiled off regardless of the level of water in the pot. This is why simple ratio formulas (like 2 to 1) don’t work. Two cups (versus one cup) of rice will need two cups of water to be absorbed into the rice and one extra (not two) to be lost to vapor. This is why many experienced rice cooks usually measure a relatively constant level (like ½ inch) of water above the level of the rice, regardless of the quantity of rice. By far the best solution is to have a good rice cooker, follow the instructions, and let it take the guesswork out of the process.

Rinsing the rice. This is another issue that causes quite a bit of debate. Almost all serious consumers of rice rinse the rice thoroughly before cooking. There are good reasons to do so. Cooking instructions in the U.S. instruct you not to rinse the rice. By law, rice for the consumer in the U.S. has been fortified with powdered vitamins that are removed when rinsed. If you want the vitamins (which are not necessary with a well balanced diet), then do not rinse. If you want the best quality cooked rice, then rinsing helps. The difference is subtle, but a real rice consumer can tell the difference. Sage V Foods did exhaustive studies on washing rice before putting in equipment to wash rice before grinding it into flour for the Japanese market. It seemed like such a waste of money and effort to wash and dry rice prior to grinding into flour. But we learned that some bran (with free fatty acids) and other contaminants do remain on even the best milled rice and the flavor is cleaner when the rice is washed. The whiteness improves and much of the loose surface starch is removed. The rice will be cleaner and less sticky when cooked. (This is preferred even for sticky type rice.) And of course, the flavors of the vitamins are removed.

Soaking the rice. Soaking the rice reduces the cooking time of the rice and improves the final cooked texture. Rice is not done until the center is cooked. Moisture does not transfer easily through rice. It take about 15 minutes in boiling water to get water and heat to the center of the kernel. So the outside of the kernel has been cooked for 15 minutes while the center has been cooked only a minute or so. The more the outside of the kernel cooks, the more starch leaches out and the mushier it gets. Soaking white rice for about an hour before cooking allows moisture to get to the center of the kernel. During cooking, the heat will transfer quicker to the center and the rice will be done in six to eight minutes causing less damage to the outside of the kernel.

Blanching or boiling the rice. The rice needs to cook in hot water in order to get additional moisture into the rice and transfer the heat necessary to gelatinize the starch. It is possible to steam cook rice, particularly if water is added during the process.

Steaming. Steaming is an important part of the cooking process. Steaming rice that has been blanched helps more evenly distribute moisture within the kernel (from the outside to inside). Steaming allows further cooking of the rice without the starch loss and swelling damage that occurs in blanching. Steaming helps heal cracks in the rice.

The rice cooker. The rice cooker does a great job of handling all of these processes. The rice can be placed in the cooker one hour early to soak. (most people skip this process). When the cooker is turned on, the blanching process starts. As the water level drops, the upper layers of rice get steamed. The rice steams in the cooker until temperatures exceed 212 and the cooker cuts off. Vapor and water cannot exceed the temperature of 212, and so the cooker knows all water is gone when the temperature exceeds this level. (The secret of how the cooker knows the rice is ready.)

Brown Rice and Wild Rice. Both of these types of rice have a thick bran layer that is coated with a waxy layer. It is very difficult for moisture to penetrate these layers. Requirements for cooking and soaking times are dramatically increased to almost an hour, but the cooking process remains the same.

Parboiled Rice. The parboiling process makes parboiled rice an almost indestructible kernel. Parboil rice does not readily continue to take up moisture when over cooked and does not easily get mushy. Parboiled rice can be boiled with excess water and then drained. The quality of parboiled rice cooked in this manner is almost as good as the full cooking process.

Arborio or Carnaroli Rice. When used in Risotto, these rice types are cooked in a different manner. The rice is first cooked in the skillet with oil or butter until translucent to change the nature of the starches in the surface of the kernel. Then cooking stock (chicken, vegetable, mushroom, ect.) is added in increments and stirred in. The rice is intentionally overcooked (more than 15 minutes). The resulting product has a creamy starchy surface and yet a firm bite through the kernel.

Commercial Rice Millers – Milling is a crucial step in post-production of rice. The basic objective of a rice milling system is to remove the husk and the bran layers, and produce an edible, white rice kernel that is sufficiently milled and free of impurities.